CREPE WEAVES:

Crepe weaves constitute an useful variety of simple weaves and are also known as “crape” or “oatmeal” fabrics due to their pebbly or crinkled (rough) surface. The size of the pebbles and their arrangement on the fabric surface determine the type of crepe fabric.

The crepe effect can be achieved either by the use of crepe yarns (highly twisted) or a crepe weave, and sometimes by special process of finishing, i.e., embossing. Crepe weaves are commonly used in combination with other elementary weaves, to produce a variety of various effects in elaborate jacquard designs for brocade and related fabrics.

The crepe weaves are characterized by the following features :

- They contain no twilled or other prominent effects

- The cloth is covered by minute spots or seeds

- Highly irregular surface-puckered in appearance

- High twist yarns are used with controlled shrinkage

- Formed mainly by four methods, though several methods are available.

Crepe weaves are constructed in a variety of forms based on the end use requirements and the type of texture desired. They are accordingly produced in light, medium and heavy constructions. Generally the count of the warp yarns used is finer than the weft yarn. The weave employed is of an irregular nature. Though several methods are employed in the construction of crepe weaves, four methods are chiefly employed,

- Construction of crepe weaves upon sateen base

- Combination of a floating weave with plain threads

- By reversing a small motif

- Insertion of one weave over another.

CONSTRUCTION OF CREPE WEAVES UPON SATEEN BASE:

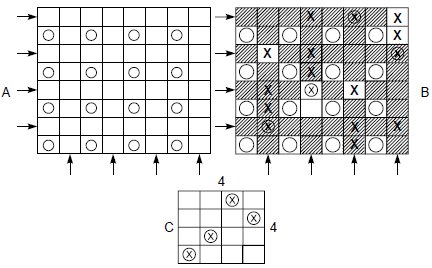

In this case the base weave is a sateen, upon which a chosen weave is inserted to get the irregular effects. This is shown in Fig.

|

| Crepe Weave upon Sateen Base |

At Fig. A, is shown the base sateen weave and at Fig. B, is shown the crepe effect obtained by insertion of a twill weave (3/1 and 1/3) upon the sateen base. The sateen weave has been marked with a different notation in order to identify the base weave.

COMBINATION OF A FLOATING WEAVE WITH PLAIN THREADS:

In this method a floating weave is inserted upon a plain weave to get the desired crepe effect as shown in Fig.

|

| Combination of a Floatiing Weave with plain threads |

At Fig. A, is shown the insertion of plain weave. The arrow marks indicate the boxes where the floating weave is to be inserted. The floating weave chosen here is a combination of a 4 end sateen and a twill (2/1 and 1/3). At C, is shown the 4 end irregular sateen, separately.

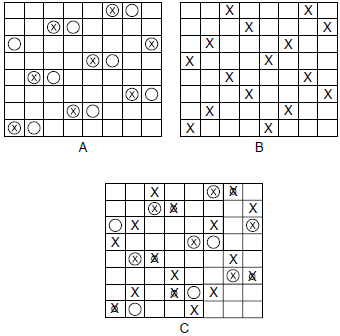

BY REVERSING OF A SMALL MOTIF:

In this method a simple motif can be chosen and reversed at intervals within the design repeat to get an irregular effect as shown in Fig.

|

| Construction of Crepe Weave by Reversing of a Small Motif |

At A, is shown a simple motif and at B, is shown the crepe designs obtained by reversal of the motif at regular intervals.

INSERTION OF ONE WEAVE OVER ANOTHER:

In this method two different weaves are chosen and are inserted over one another to get the desired crepe effect as shown in the Fig. 7.4. In order to produce an irregular effect, atleast one of the weaves should be irregular and would be better if both are irregular. Sateen and sateen derivatives are generally used in this method.

|

| Construction of crepe weave by insertion of one weave over another |

In Fig. A, is shown a sateen derivative and in Fig. B, is shown a 4 end sateen. In Fig. C, is shown the crepe effect obtained by the insertion of A over B.

TYPICAL QUALITY PARTICULARS FOR A CREPE FABRIC:

A typical type of a cotton crepe fabric of good quality and medium weight should have the following

specifications :

Warp - 18s

Weft - 18s

Warp threads/inch - 56

Weft threads/inch - 56

Warp yarn should have a little more twist than the weft.

END USES OF CREPE WEAVE:

Crepe weaves are frequently employed in conjunction with other elementary weaves, in order to produce a variety of different and contrasting effects in elaborate jacquard designs for brocade and similar fabrics. They are also employed in the production of cotton piece goods that are usually woven in the grey state, to be afterwards bleached and used for a variety of domestic purposes. Crepe fabrics are also sometimes printed with decorative designs and sold as a light and cheap material known as “cretonne”, which is employed extensively as loose coverings for furniture, antimacassars, covers, curtains and wall hangings, and for many other similar household articles.

That's very useful. Yarn twist is defined by the degree of tightness applied to the fiber and it is normally measured by the number of twist of unit length. Generally, the unit length for staple yarn is “10cm”, and the length ratio is “1m”. The higher the number of twist in a particular length, the higher the yarn twist.

ReplyDeleteGreat tips Thank you for this information. It is really informative and helpful for the people.Custom Print French Terry Fabric

ReplyDeleteGreat piece of information! Keep posting such things. Weavers worldwide are really appreciating such efforts!

ReplyDeleteHelpful

ReplyDeleteNice post. Textile Ebook

ReplyDeletehi was just seeing if you minded a comment. i like your website and the thme you picked is super. I will be back

ReplyDeleteריצ'רד טוויל

Visit Jagdish Wines L1 for Home Delivery Of Wines In Gurugram.

ReplyDeleteGud work...😇

ReplyDeleteNice Blog!!

ReplyDeleteThanks for sharing valuable information through this blog.

Solvent Dyes Manufacturers in India

Dye Manufacturers in India

Roll-Up Covers:

ReplyDeleteMiller Machine & Fabrication, Inc.

Specializes in custom roll-up covers for various industrial applications.

Website: Miller Machine & Fabrication

Beltservice Corporation

Offers a range of roll-up covers and industrial belting solutions.

Website: Beltservice Corporation

Roll-Up Cover Company

Provides a variety of roll-up covers for machines and equipment.

Website: Roll-Up Cover Company

Rollup Covers manufacturer

Laser Machine Bellows manufacturer

Bellows Covers manufacturer

I love what you share amazing information Rollup Covers manufacturer

ReplyDeletePost a Comment