WELTS AND PIQUES:

Welts and piques are characterized by more or less pronounced ridges and furrows producing a series of ribs, welts or cords with a surface tissue of the plain calico weave, and extending in parallel lines transversely across the width of the fabric, i.e., in the direction of the weft threads. A pique structure consists of a plain face fabric composed of one series of warp and one series of weft threads, and a series of back or stitching warp threads. The stitching ends are placed on a separate beam which is heavily weighted to provide greater tension to the stitching warp.

The loom equipment necessary for manufacturing pique structures are a dobby loom with two warp beams (one for face warp under normal tension and another for stitching warp under heavier tension), a fast reed beat up mechanism and drop boxes ( 2 ¥ 1 or 2 ¥ 2), for wadded designs.

The tight stitching ends are interwoven into the plain face texture, with the result that the latter is pulled down and an indentation is formed on the surface. In order to increase the prominence of the unstitched portions of the cloth, wadding picks are normally inserted between the tight back stitching ends and the slack face fabric.

Pique fabrics are mainly manufactured entirely of cotton woven in the grey or natural state and then bleached. They are produced in a variety of different textures, according to the purpose for which they are intended.

STANDARD QUALITY PARTICULARS:

Face warp : 30s - 60s

Stitching warp : 20s - 2/30s

Weft : 40s - 70s

Ends/inch : 92 - 132

Picks/inch : 96 – 152

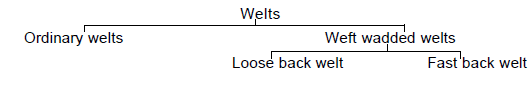

CLASSIFICATION OF WELT STRUCTURES:

Welt structures are classified as shown below:

ORDINARY WELT STRUCTURES:

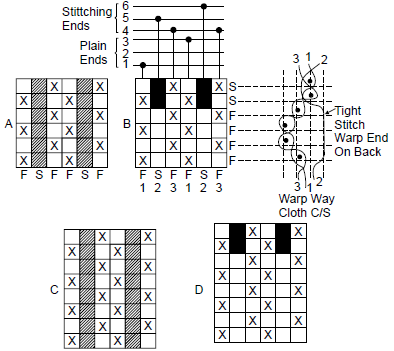

In these types of welt structures the indentations form continuous sunken lines which run horizontally in the cloth. The number of face picks in the width of a cord is varied according to requirements, but usually the number of consecutive picks that are unstitched should not exceed twelve. Figure 9.1 shows the design of ordinary welt structures.

|

| Design of ordinary welt structure |

In the above figure, is shown some ordinary welt structures. Figs. A, C and E show the first stage in the construction of ordinary welt structures and Figs. 9.1 B, D and F show the corresponding final designs. The three different welt designs shown above are constructed on repeats of 6, 8 and 18 picks respectively. The ratio of the face to stitching warp is 2 : 1. The stitching ends are indicated by shaded squares. The ends are arranged in the order of one face, one stitching and one face, in each split of the reed. In the final designs B, D and F, the solid marks indicate the lifts of the tight stitching ends into the plain face texture on two consecutive picks.

WEFT WADDED WELTS:

In the case of welt structures wadding threads can be introduced weft way. The object using the wadding threads is to enhance the prominence of the horizontal cords, and to make the cloth heavier. The wadding weft is coarser than the ground weft and is inserted as a pair of picks at a place. This is achieved with looms provided with multiple shuttle boxes at one side only. The face ends are lifted over the wadding picks, while the stitching ends are left down. Sometimes, the same kind of weft is used for both the face and the wadding. In such cases looms with a single box at each side are employed, and in such cases, one wadding pick at a place may be inserted.

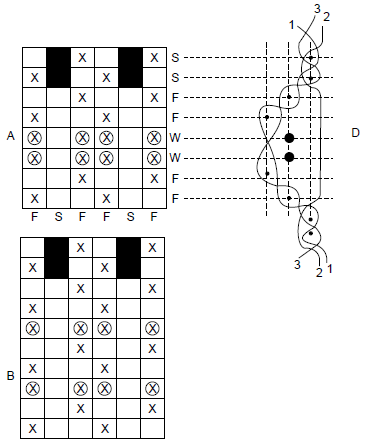

Wadding picks are inserted only as extra picks and the take up motion is either rendered inoperative on wadding picks, or it is worked out in terms of the face picks only. Fig. 9.2 shows the various designs of weft wadded welt structure.

|

| Design of weft wadded welt structure |

Fig. A, B and C show the design of weft wadded welts repeating on 8, 10 and 24 picks respectively. The stitching warp is indicated by the solid shade, the wadded thread by circled cross mark and the plain threads by cross mark. As can be seen from the designs, the stitching takes place on three picks. Figure D shows the weft way cross sectional view of design A.

FAST BACK WELTS:

In these types of structures the stitchings are interwoven in plain order with all, or some wadding picks. Whereas in ‘loose back’ type of structures (previous two types) the stitching ends are only lifted to form the indentations. In case of fast back welts, the reduction of the float length of the stitching ends on the back of the fabric helps to produce a more serviceable cloth less liable to accidental damage. Fig. 9.3 shows the design of a fast back welt structure.

|

| Design of fast back wadded welt structure |

Figure A shows the design of a fast wadded welt structure and figure B, shows the weft welt cross section. The numbered threads represent the face and stitching warp.

END USES OF WELTS:

Welts find uses in shirtings, ties and vestings.

Whether you are involved in affiliate marketing, selling items through ClickBank, or promoting your own personal business and website, ads are an important part of one's success. Some people make a recurring income simply by placing advertisements on the websites that get a lot of traffic.

ReplyDeleteריצ'רד טוויל

Great content you are providing. Textile waste management

ReplyDeleteThankyou for this informative article. Here Wallex Home Appliances is an emerging brand in the electronic and home appliances sector, offering a diverse range of products designed to enhance the modern household.

ReplyDeletePost a Comment